UV Printing Foam PVC For Advertising

Our PVC Foam Board is a versatile and reliable solution, perfect for a wide range of industries and applications. Made from high-quality materials, it offers exceptional performance with a range of fabrication and processing options.

Whether for professional signage or industrial use, our foam board meets the demands of quality and durability while providing excellent cost-effectiveness.

Key Features

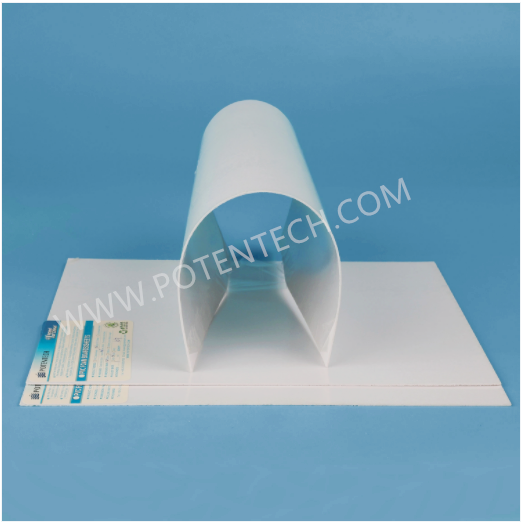

Easy to Work With: Fabricate with standard tools like saws, drills, and heat forms, making it user-friendly for a variety of projects.

Lightweight: Easy to handle and transport without compromising on strength or durability.

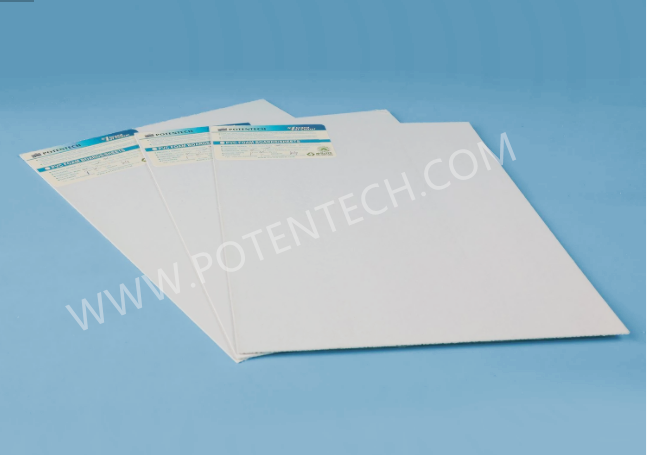

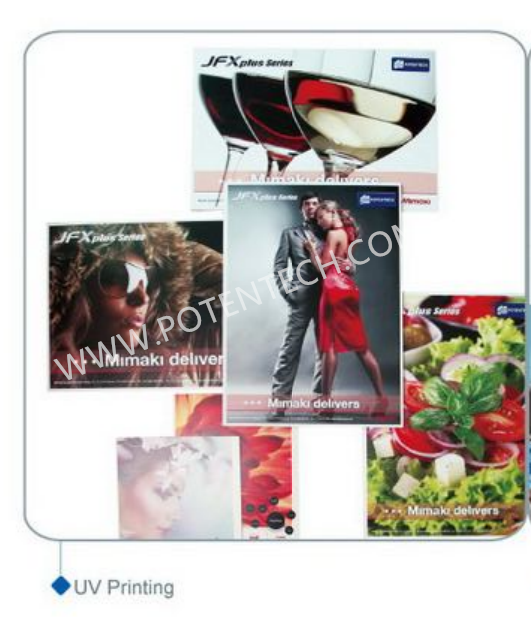

Superior Printability: Ideal for digital printing, creating vivid and long-lasting graphics.

Fine Cell Structure: Provides a smooth, uniform surface, making it perfect for precise fabrication and clean finishes.

Low Flammability: Rated UL 94 V0 Self Extinguishing, ensuring higher safety standards for your applications.

Non-Corrosive & Non-Toxic: Safe to handle and environment-friendly, with no heavy metals.

Impact Resistance: Tough and durable, able to withstand impacts while maintaining its structural integrity.

Chemical & Moisture Resistant: Perfect for harsh environments, offering protection against chemical exposure and moisture damage.

Thermal Insulation: Better insulator than wood, helping to maintain temperature regulation in various applications.

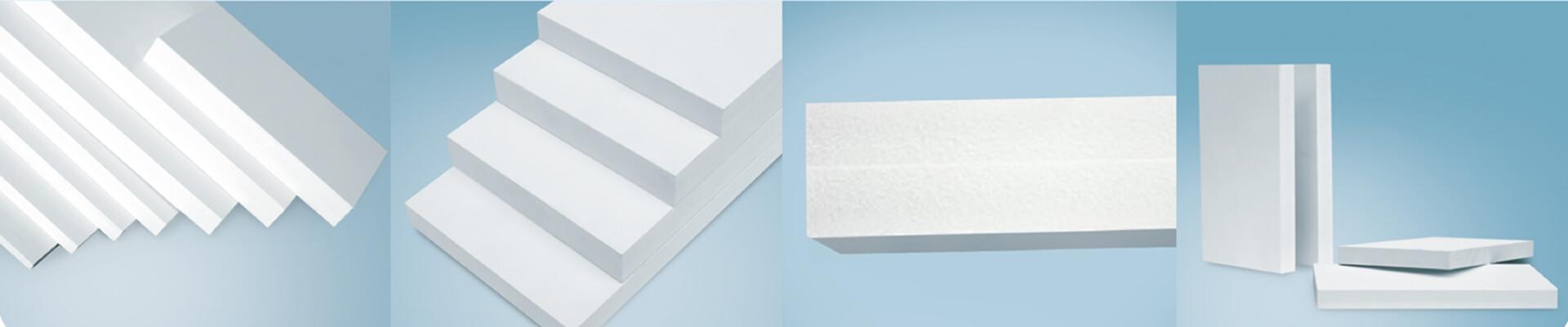

Fabrication Options

Rout

Screw

Engrave

Rivet

Heat bend/form

Die cut

Saw/Cut

Paint

Drill

Photo/Print

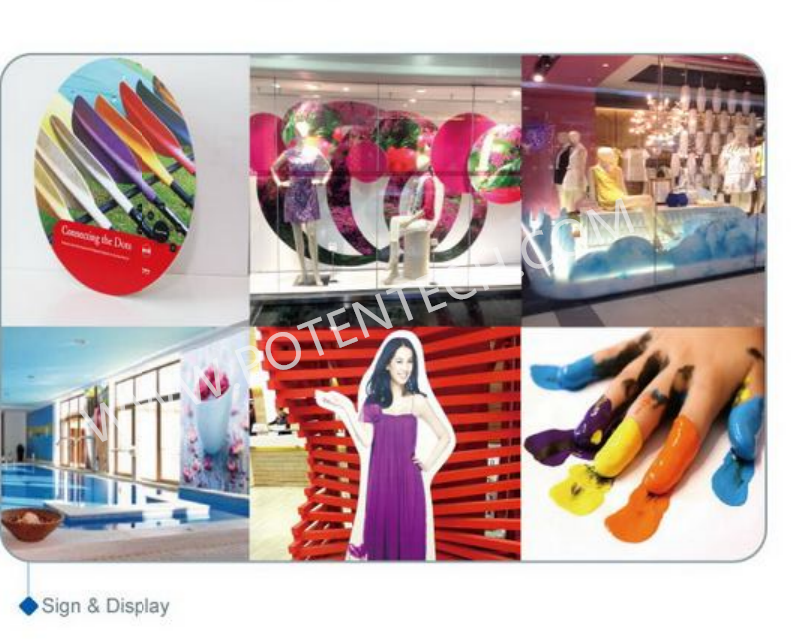

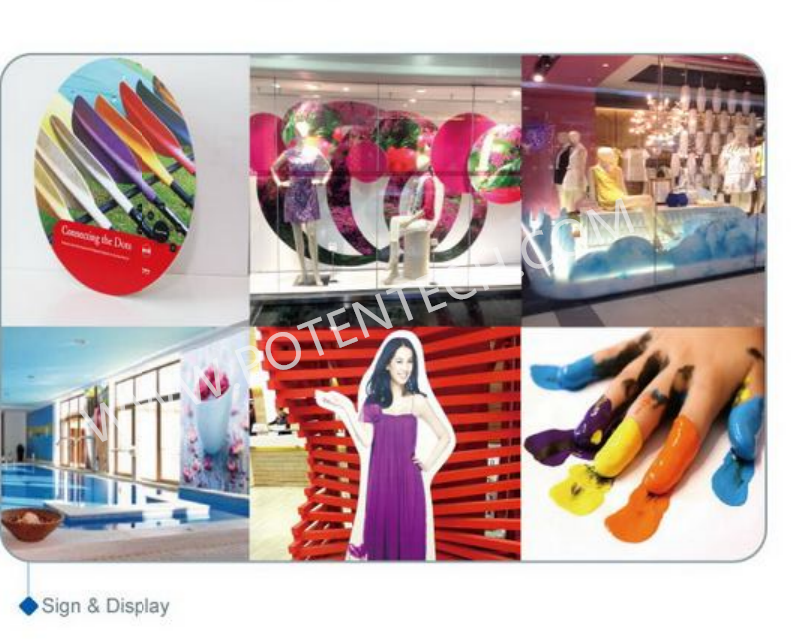

Applications & Markets

PVC Foam Board serves a wide range of industries, making it an ideal solution for various applications such as:

Advertising Signage: Lightweight and easy to display, perfect for both indoor and outdoor use.

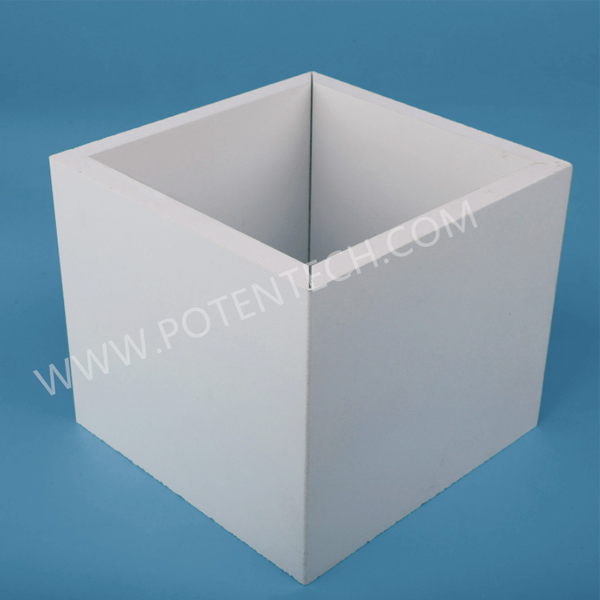

POP Displays: Create attractive and durable point-of-purchase displays.

Furniture: Ideal for building custom furniture pieces that are both durable and lightweight.

Exhibit Stands and Panels: Excellent for trade shows and exhibitions, offering ease of use and high visual impact.

Models and Prototypes: A great material for crafting precise models and prototypes.

Marine Applications: Used in boat panels and cabins due to its moisture resistance and durability.

Embossing/Engraving: Can be easily engraved for custom designs or signage.

Thermoforming: Ideal for creating intricate shapes and molded designs.

Retail Merchandising: Perfect for creating eye-catching displays and fixtures.

Wood Replacement: A reliable, lightweight alternative to traditional wood in many applications.

Digital Printing: High-quality material for vibrant, long-lasting prints.

Dimensional Lettering: Great for creating 3D lettering and signage.

Refrigeration: Used in refrigeration units for insulation and paneling.

Cabinetry & Furniture: Used in cabinetry and furniture making for its strength, appearance, and versatility.

Vehicles: Excellent for use in ambulances, RVs, and other vehicles, providing durability and a high-quality finish.

For Silk Screen Printing

For caving

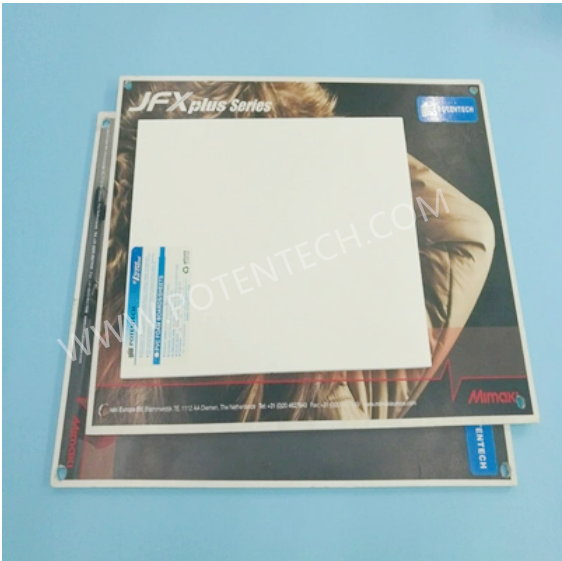

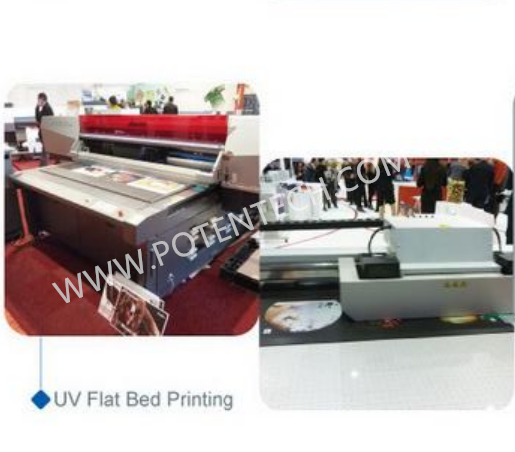

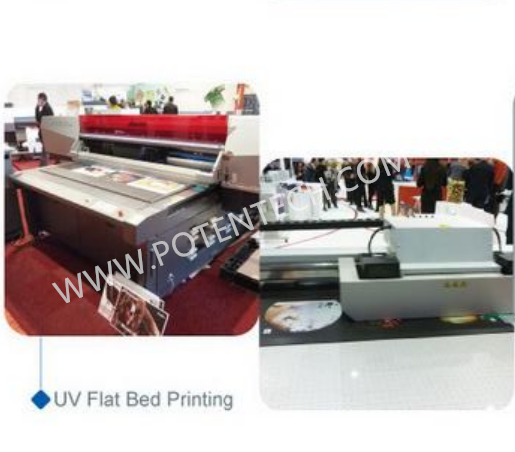

For UV Flat Bed Printing

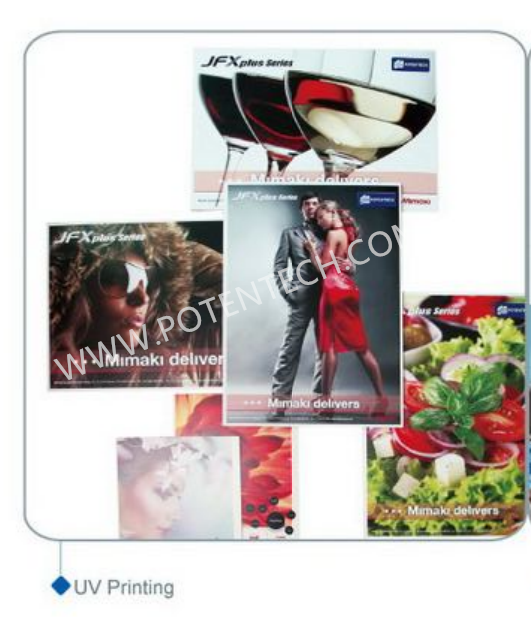

For UV Printing

For Display Application

RECOMMENDATIONS FOR THE PREPARATION FOAM PVC SHEETS

Static Electricity is a natural environmental phenomenon that can produce unacceptable results in digital printing applications. The ultra fine inkjet nozzles in modern printing equipment fire miniscule droplets of ink onto the surface of the print media and the presence of static electricity can cause these droplets to deflect from their intended path, resulting in variable ink coverage across the media.

Many of the substrates used within the Digital Print industry can be sensitive to static and it is vital that all precautions are taken when preparing these materials before printing. Listed below are a series of recommendations relating to the preparation of Foam PVC Sheets prior to processing through a digital print machine.

MATERIAL HANDLING & STORAGE

Always use lint free gloves when handling sheets and ensure that FOAM PVC SHEETS' surface to be printed is not touched by uncovered hands, as this can leave a greasy residue on the sheet.

Avoid dragging sheets across each other, as this can impart additional and unwanted static into the material.

Allow newly delivered material time to settle before printing, as movement during transportation can cause an increase in static.

HUMIDITY & TEMPERATURE

Humidity & temperature can have a direct influence on the static levels within all materials includes FOAM PVC SHEETS:

Try to maintain the relative humidity at 50% or more within the area of the printing machine. This can be controlled with the use of a Hygrometer

Avoid fluctuations in temperature around the machine by keeping doors and windows closed and minimising drafts and areas of rapidly moving air.

REDUCING STATIC ELECTRICITY

The use of professional ionizing equipment is the most effective way of discharging static electricity and it is recommended that ionization should take place immediately prior to printing.

Anti-static Bars are now standard on many machines and in most cases these can also be retro-fitted to printers that do not already have one installed.

Ionizing Air Pistols are also highly effective. They replace the need to wipe the sheet with an anti-static brush or cloth whilst also ionizing the surface at the same time.

Anti-static brushes are less effective than a bar or a pistol but can be used in the absence of the other two options.

It is in the interest of the printer to ensure that all static is discharged from substrates prior to digitally printing them. It is also recommended that trials be carried out on any substrate to ensure that the optimum print results are obtained.