In the selection of construction, advertising and decoration materials, Acrylic boards and PVC foam boards are two common materials. While they may have similar uses in some applications, there are significant differences in composition, physical properties, cost, application and environmental performance. Understanding these differences can help you make informed choices based on your specific project needs.

Composition and manufacture

Acrylic sheets, also known as Plexiglas sheets, are made from polymethylmethacrylate (PMMA). PMMA is a transparent thermoplastic known for its excellent optical properties and high light transmittance. The manufacture of acrylic sheets typically involves the polymerization of methyl methacrylate monomer, resulting in a strong and durable material that can be easily processed into a variety of shapes and sizes.

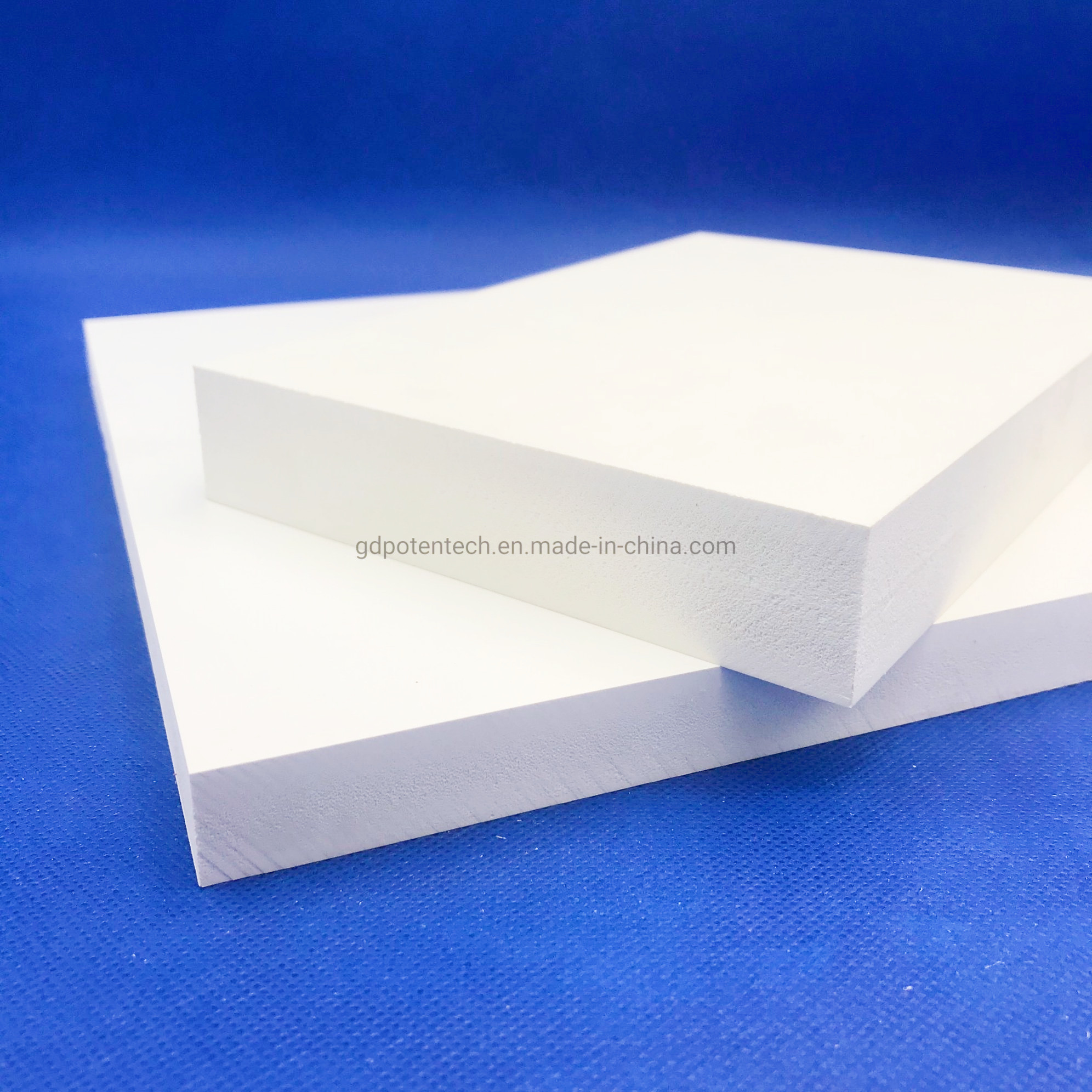

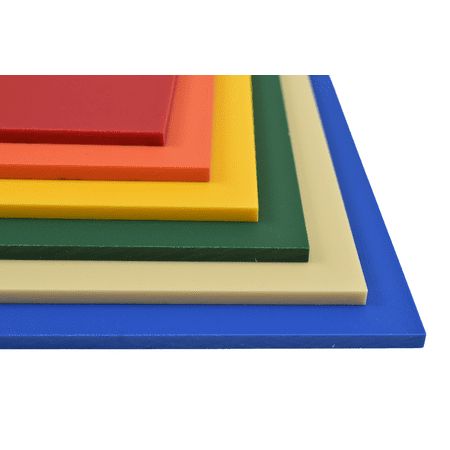

PVC foam board, that is, polyvinyl chloride foam board, is made of polyvinyl chloride (PVC) material through a foaming process. PVC is a durable and chemically resistant plastic. Through the foaming process, a tiny bubble structure is formed inside the PVC foam board, making it lightweight and rigid. This manufacturing process allows PVC foam board to provide structural strength while remaining lightweight.

Physical properties

Acrylic sheets are known for their excellent optical transparency and high light transmittance, with a light transmittance of up to 92%, which is better than many glass products. Therefore, it is often used in applications that require high transparency and aesthetic effects, such as advertising signs, display cabinets and architectural decoration. Acrylic panels also have excellent weather resistance and are not prone to yellowing or deterioration even if exposed to sunlight for a long time.

PVC foam board is known for its strong, durable and waterproof properties. Although it is not as light-transmitting as acrylic sheets, its density and strength make it excellent in applications that require load-bearing and impact resistance. PVC foam board has a smooth surface and is easy to print and coat. It is widely used in billboards, construction templates, furniture and other fields. In addition, PVC foam board also has good flame retardant properties, which has advantages in environments with high fire protection requirements.

Cost and availability

In terms of cost, PVC foam board is usually more economical than acrylic board. This cost-effectiveness makes PVC foam boards very popular for large-scale industrial and construction projects. In addition, PVC foam boards are in sufficient supply on the market with various specifications to meet various application needs.

In comparison, the cost of acrylic sheets is higher, but its excellent optical properties and aesthetic effects can often offset its high price. In high-end applications, acrylic sheets are considered a material worthy of investment, especially in projects that require high transparency and visual appeal.

Application areas

Acrylic panels are widely used in advertising signs, display cabinets, light boxes, architectural decoration and other fields due to their transparency and processing flexibility. Not only does it provide excellent visual effects, it is also easy to cut, carve and thermoform, suitable for a variety of creative designs.

PVC foam board is commonly used in construction, furniture manufacturing and advertising due to its durability and waterproof properties. For example, building formwork, partitions, display boards and billboards are all common applications of PVC foam boards. Its surface is flat and easy to print, making it suitable for making various outdoor and indoor billboards.

Environmental performance and recycling

With the improvement of environmental awareness, the environmental performance of materials has become one of the important considerations in selection. Acrylic panels are a recyclable material that can be reprocessed and reused through appropriate recycling processes to reduce environmental impact. However, the production of acrylic sheets involves the use of some petrochemical raw materials, and how to further reduce the carbon footprint in its production process remains a challenge.

PVC foam boards also face similar problems in terms of environmental protection. While PVC itself is recyclable, some additives used in its production, such as plasticizers and stabilizers, can have potentially negative impacts on the environment and human health. To this end, researchers and manufacturers are working hard to develop more environmentally friendly production processes and recyclable solutions to reduce the environmental burden of PVC materials.

In conclusion

Acrylic boards and PVC foam boards have their own advantages and disadvantages in terms of composition, physical properties, cost, application and environmental performance. Acrylic boards are suitable for applications requiring high visual effects due to their excellent transparency and aesthetic effects; while PVC foam boards occupy an important position in construction, advertising and industrial applications due to their durability, economy and waterproof properties. Understanding these differences can help make the best choice based on specific project needs, ensuring effective application of materials and rational use of resources.