In the home improvement industry, the choice of materials is crucial.

Especially for kitchens, bathrooms and other Spaces with high moisture and mildew requirements, the production materials of cabinets need to be carefully selected.

In recent years, PVC board in the production of cabinets has become more and more extensive, mainly PVC Celuka, but recently, PVC Co-extrusion board also gradually be popular.

What is difference between them?

PVC Co-extruded board

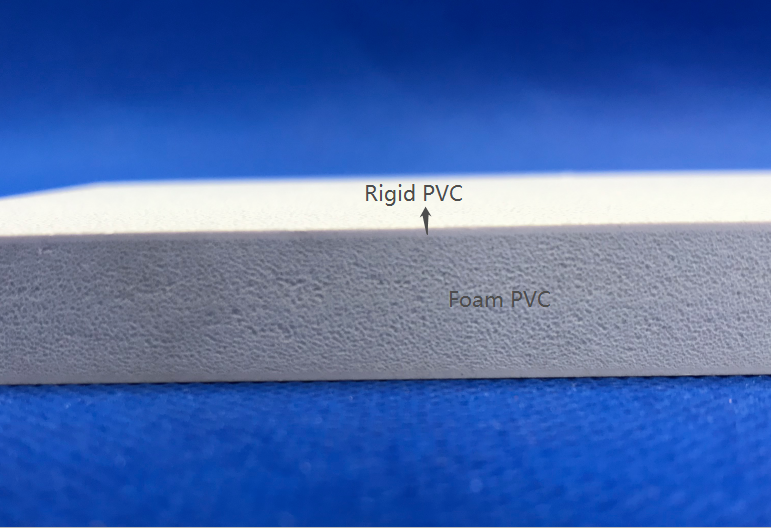

PVC Co-extruded Board is a kind of material produced by two extrusion outlet with two materials, of which the surface layer is rigid PVC and the core layer is foam PVC.

Those are why PVC Co-extruded board with high surface hardness and excellent impact resistance.

PVC Co-extruded board

The hardness of the co-extruded board is higher, which makes it a significant advantage when used as a cabinet back. For example, in cabinet backer, PVC Celuka usually need 5mm to achieve the required rigid and hardness, while co-extruded boards may only need 3mm to achieve the same hardness requirements.

This not only improves the efficiency of material use, but also reduces the weight and is more convenient for installation and transportation.

Disadvantages of PVC co-extruded board

Despite the many advantages of co-extruded panel, it is relatively costly. This is mainly because the co-extrusion process is complex, and the precise matching of two layers of materials is required in the production process, resulting in increased production costs.

Therefore, consumers need to consider budget issues when choosing a co-extrusion board, weighing the relationship between price and performance.

PVC Celuka

PVC Celuka is a material produced by foaming process, its surface and core layer are extruded by the same extrusion outlet, through the process method, so that it forms a smooth surface.

The production cost of crust board is relatively low because of its simple foaming process, high material utilization, and low energy consumption in the production process. This makes celuka board competitive on price and an affordable option.

PVC Celuka

Disadvantages of PVC Celuka

The structure of the PVC Celuka determines its lower physical strength compared with PVC Co-extrued board, especially in the case of bending and deformation strength.

Therefore, the thickness needs to be selected in the application to ensure that it can meet the requirements of use. In the application of the cabinet back, it is usually necessary to choose a thicker crust board to provide sufficient hardness and strength.

Comprehensive comparison

In the comprehensive comparison of PVC coextruded board and PVC Celuka , we can see that both have advantages and disadvantages.

The co-extruded board has high hardness, and is suitable for parts that require high strength and high hardness, such as the backer of tthe cabinet, but its cost is higher.

PVC celuka board is light weight and easy processing, and is suitable for parts that need moisture-proof and insulation, such as kitchen and bathroom cabinets, but its hardness and strength are low, and the appropriate thickness needs to be selected.