Waterproof Glossy Surface PVC Rigid Foam Board For House Furniture

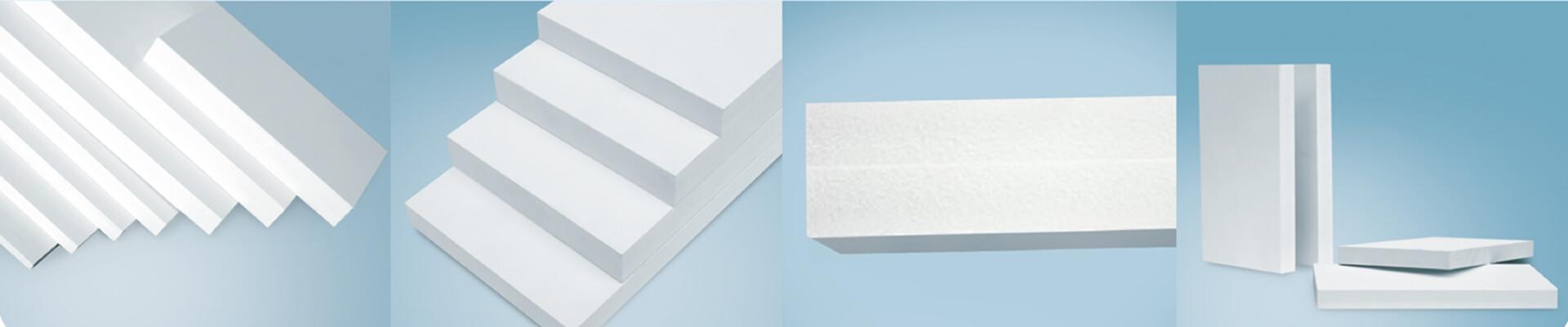

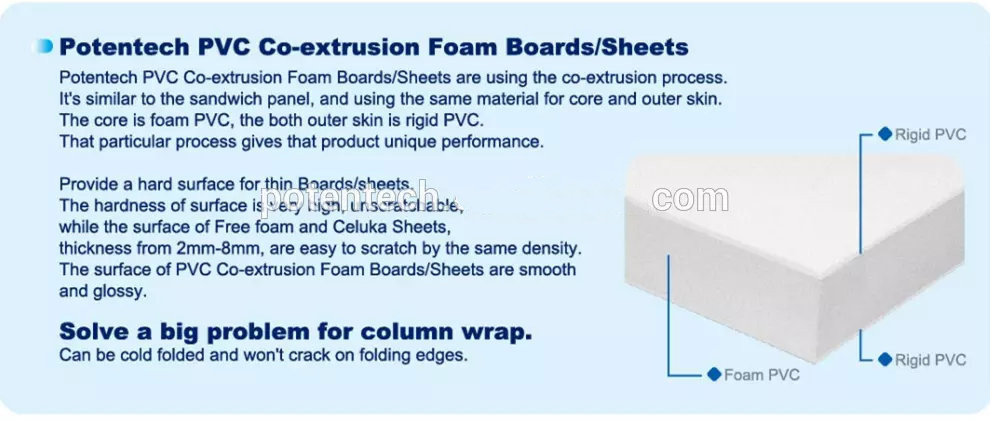

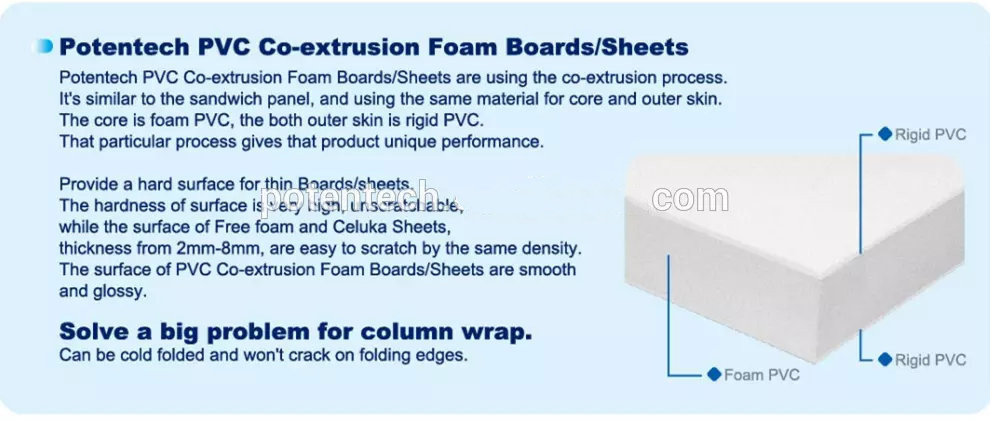

Potentech Rigid PVC Furniture Board( PVC Co-extrusion Foam Boards/Sheets) are using the co-extrusion process.

PVC Co-extrusion Foam Boards/Sheets is similar to the sandwich panel, and using the same material for core and outer skin.

The core is foam PVC, the both outer skin is rigid PVC.

That particular process gives that product unique performance.

Rigid PVC Furniture Board provide a hard surface for thin Boards/sheets.

The hardness of surface is very high, unscratchable, while the surface of Free foam and Celuka Sheets,thickness from 2mm-8mm, are easy to scratch by the same density.

The surface of PVC Co-extrusion Foam Boards/Sheets are smooth and glossy.

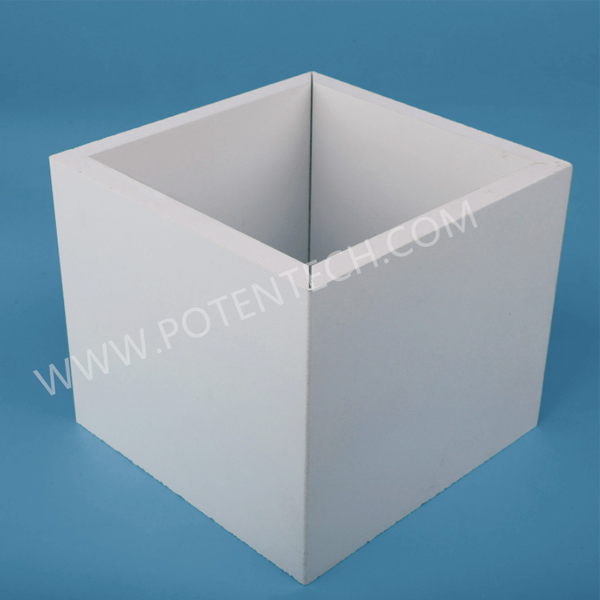

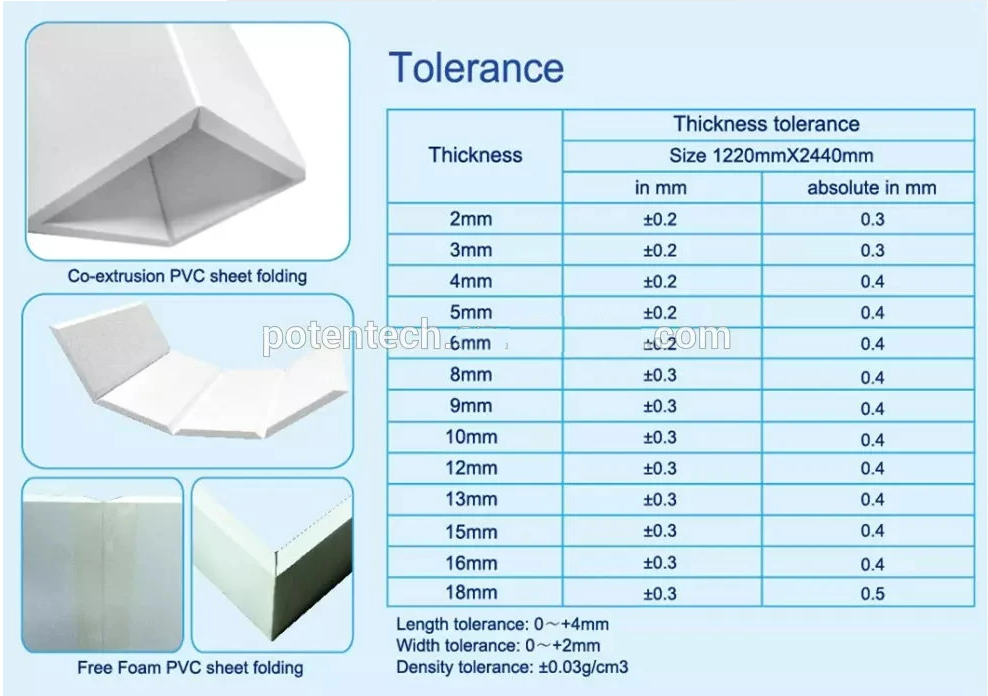

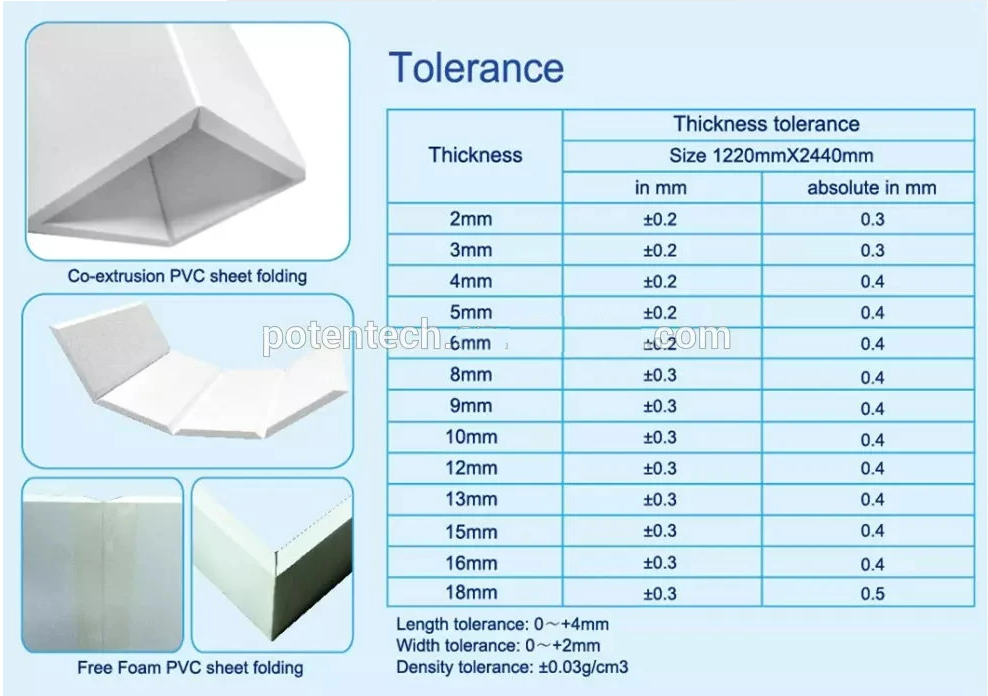

Potentech Rigid PVC Furniture Board( PVC Co-extrusion Foam Boards/Sheets) solve a big problem for column wrap. Can be cold folded and won't crack on folding edges.

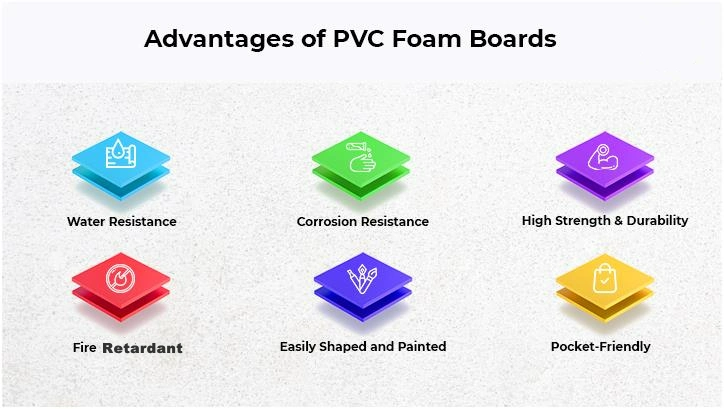

Advantages for Potentech PVC foam board:

Lightweight: PVC foam board is lightweight compared to traditional materials like wood and metal. This makes it easier to handle, transport, and assemble furniture pieces. It is especially beneficial for items that may need to be moved frequently or for projects where weight is a concern.

Durable:Despite its lightweight nature, PVC foam board is surprisingly durable. It is resistant to moisture, corrosion, and rot, making it suitable for both indoor and outdoor furniture. The material can withstand various environmental conditions, ensuring the longevity of the furniture.

Versatility: PVC foam board is highly versatile and can be easily cut, shaped, and fabricated into various furniture designs. It allows for intricate detailing and can be formed into smooth curves and edges, providing more design options and flexibility for creative furniture makers.

Low maintenance: Furniture made from PVC foam board generally requires minimal maintenance. Unlike wood, it doesn't need regular painting, staining, or sealing. Simple cleaning with mild soap and water is usually sufficient to keep it looking good for a long time.

Cost-effective: PVC foam board is often more affordable than many traditional furniture materials like solid wood or metal. This cost-effectiveness can be particularly advantageous for budget-conscious projects or large-scale furniture production.

Fire-resistant: PVC foam board has inherent fire-resistant properties, which can be crucial for ensuring safety in certain environments or applications, such as public spaces or commercial buildings.

Eco-friendly options: Some PVC foam board manufacturers produce environmentally friendly versions that are free from harmful substances like lead and heavy metals. These eco-friendly options contribute to sustainable furniture production.

Resistant to insects and pests: Unlike wood, PVC foam board is not attractive to insects and pests, which can be especially beneficial for outdoor furniture that is exposed to the elements.

Processing Capacity

Potentech have a series equipment for PVC foam board product's further processing.

Cutting, Routing, Punching, Trimming, Sawing, or Laminating.