Polyvinyl Chloride Plastics Rigid PVC Foam Board Sheet with protective film

Brand :POTENTECH

Product origin :Guangzhou,China

Delivery time :Within 1 Month

Supply capacity :20 containers per month

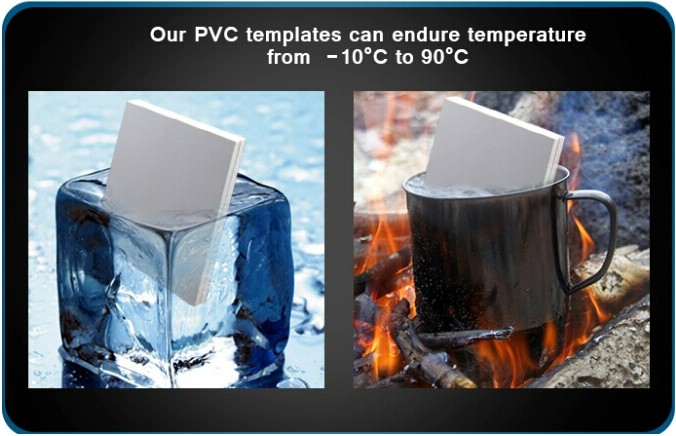

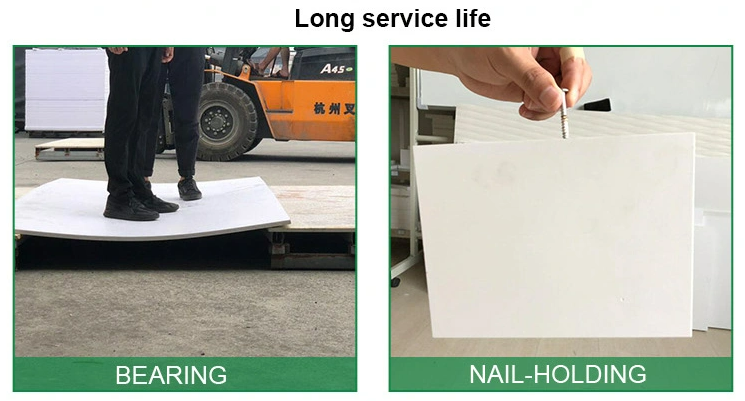

PVC Foam board is an excellent material for sanitary products, kitchen cabinets, washroom cabinets, and furniture, among other things. Perfect for making outdoor wallboards, indoor decorative boards, office and housing divider boards, and so forth. PVC Foam board is fireproof, waterproof, self-extinguishing, and resistant to acid, moth, heat, vibrations, noise, and light. Can be readily nailed, drilled, pasted, sawed, or processed in any other way. Thermal and acoustic insulation; absorbs vibrations and oscillations. Celuka Foam PVC Boards can be used for Signage, Printing, Display and exhibition boards and Interior Fit outs. The Foam PVC sheets are used as well at Trade Shows, Exhibitions as Dividers and partitioning for Bulletin boards in Cool rooms and Caravans and boats.

Potentech PVC Foam Boards/Sheets and Mouldings' outstanding product characteristics open up a highly diverse range of potential applications.

Polyvinyl Chloride Plastics Rigid PVC Foam Board Sheet with protective film

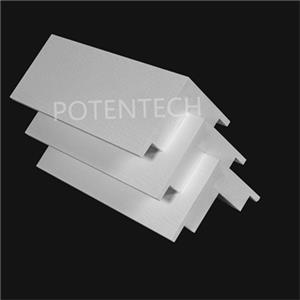

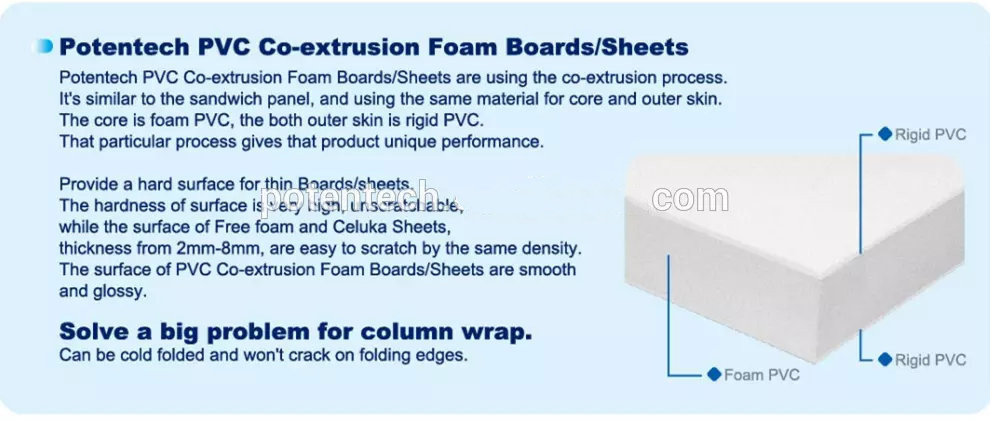

Potentech Rigid PVC Furniture Board( PVC Co-extrusion Foam Boards/Sheets) are using the co-extrusion process.

PVC Co-extrusion Foam Boards/Sheets is similar to the sandwich panel, and using the same material for core and outer skin.

The core is foam PVC, the both outer skin is rigid PVC.

That particular process gives that product unique performance.

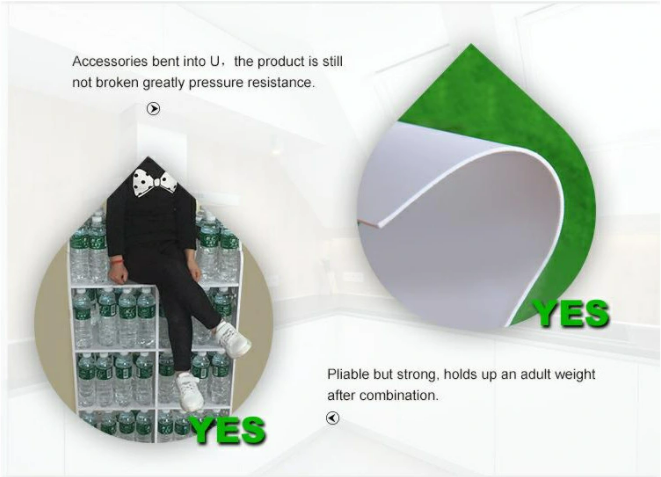

Rigid PVC Furniture Board provide a hard surface for thin Boards/sheets.

The hardness of surface is very high, unscratchable, while the surface of Free foam and Celuka Sheets,thickness from 2mm-8mm, are easy to scratch by the same density.

The surface of PVC Co-extrusion Foam Boards/Sheets are smooth and glossy.

Potentech Rigid PVC Furniture Board( PVC Co-extrusion Foam Boards/Sheets) solve a big problem for column wrap. Can be cold folded and won't crack on folding edges.

Potentech PVC foam sheets and mouldings is life time no rot warranty.

Potentech warrants to the original purchaser that each Potentech Product will be free from manufacturing defects that cause the Product to corrode, delaminate, or excessively swell from moisture for a period of thirty (30) years, from the date of the original consumer purchase.

Each Purchaser of a Potentech Product is solely responsible for determining the effectiveness, suitability and safety of any particular use or application of the Product.

Potentech reserves the right to investigate any claim hereunder

Building code regulations vary from area to area.

Each Purchaser should consult local building and safety codes for specific requirements.