2024-07-25

More

Menu

- Home

- Products

- PVC Moulding

- PVC Skirtboard

- PVC Crown Mouldings

- PVC Casing Mouldings

- PVC Beadboard

- PVC Windows Sill

- Additional Mouldings

- PVC Trim

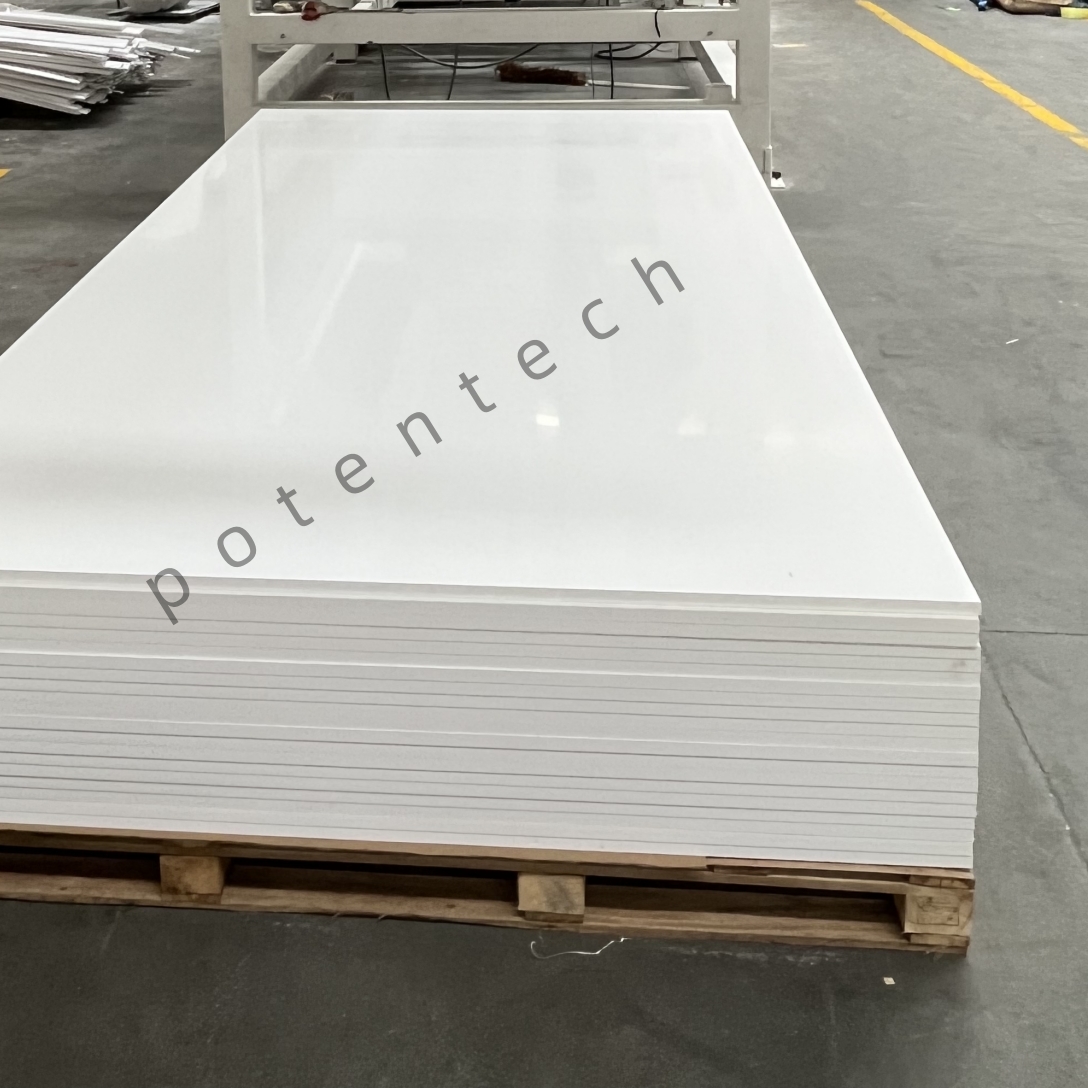

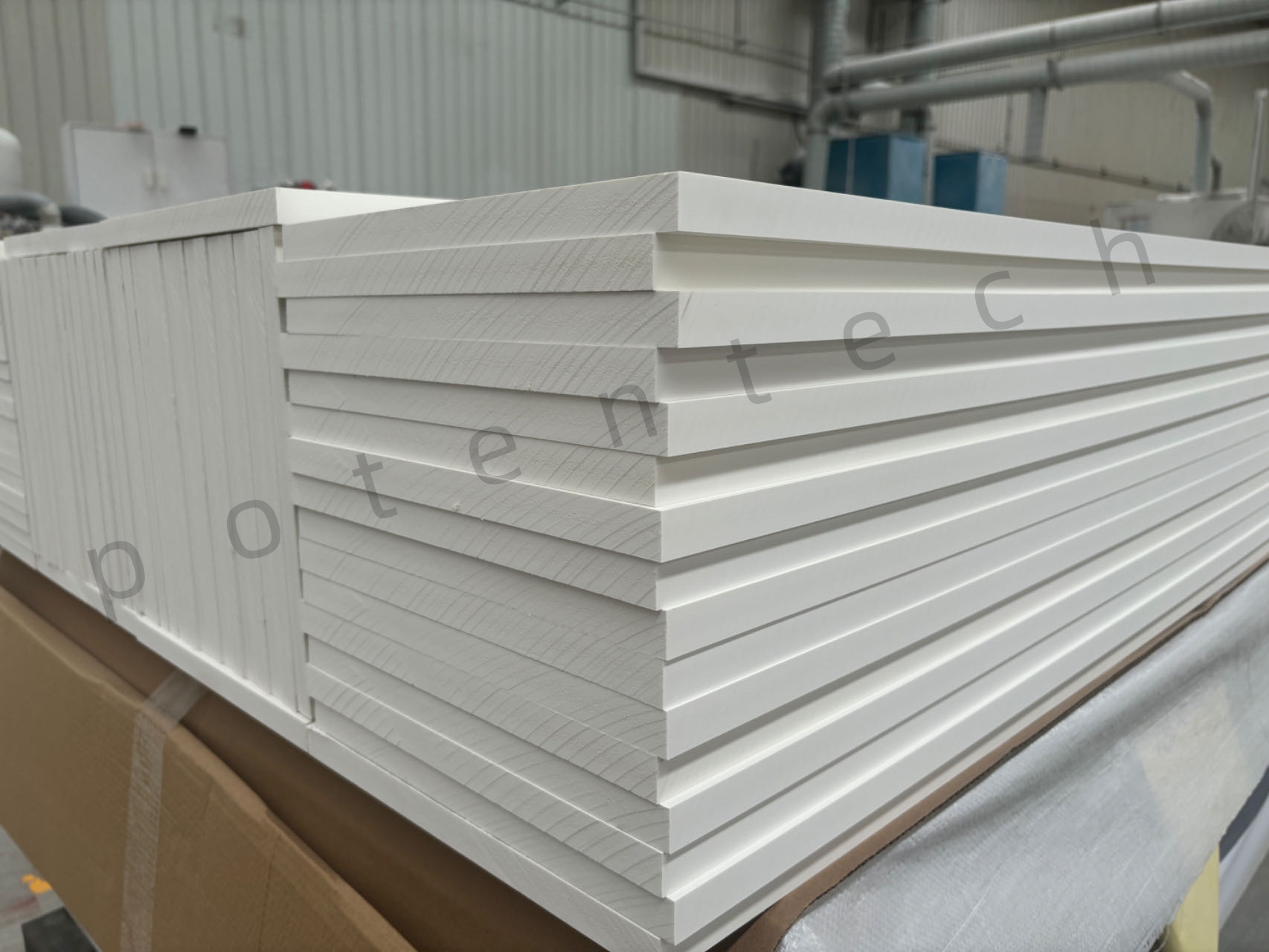

- Cellular PVC Trimboard

- PVC Conceal Trim

- Window & Door Trim

- PVC Furniture Boards

- PVC Advertising Boards

- PVC Post Wrap Boards

- PVC Lamination Boards

- News

- Company news

- Industry News

- Case

- Factory Show

- 360º Factory Tour

- Company Basic Information

- Advanced Equipments

- A Complete Quality Management System

- Contact Us

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Service

- Responsibility

Search